New Era of Express and Warehousing Industry

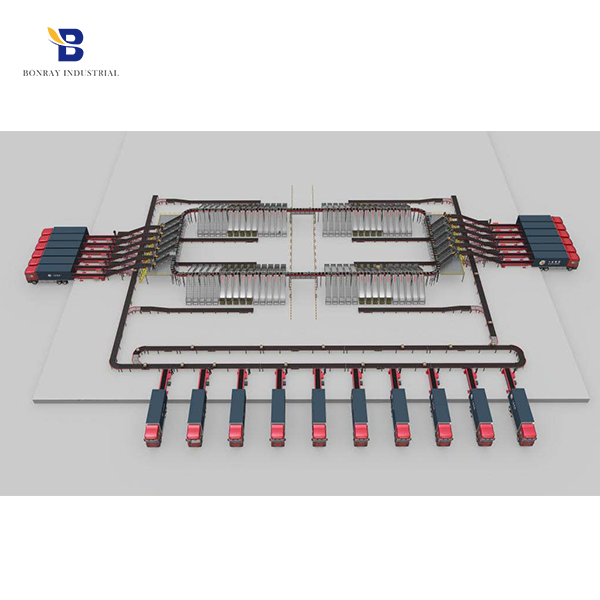

Automation has become an important measurement to express and warehousing companies. Nowadays,the automatic sorting system plays an increasingly important role in Express, Storage and Distribution fields.

The automatic sorting system can continuously sort materials in large batches. Due to the automatic operation mode, the automatic sorting system is not restricted by climate, time and physical strength. At the same time, its sorting capacity is incomparable with the manual sorting system. For example, one layer cross belt sorter can sort 20.000 pph The sorting system is 6-7 times of the manual efficiency. In addition, automatic sorting equipment is one of the key equipment in the express distribution center. Using intelligent scanning recognition, automatic sorting, transportation and other technologies, accurate and fast unmanned sorting work can be completed in the express center, and express sorting can be easily handled.

The components of the automatic sorting system can be divided into four parts: induction, sorting conveyors and carriers, sorting chute, control device and computer management.

1. Input Device

The induction includes a conveyor belt and a worktable for conveying the sorted materials to the sorter. Main functions :one is to input the information of the package into the sorting system as a sorting operation command for the package;the other is to control the time and speed of sorting materials entering the sorter to ensure that the sorter can accurately perform the sorting task. Other auxiliary conveyors transport the sorted materials to the loading platform, which can be carried out according to the requirements and conditions of the sorting system on-site.

2. Sorting and Conveying system

The sorting conveyor system is the core equipment of the automatic sorting system, which is mainly used to distribute sorted materials to designated locations. Since the sorting objects of different industries and departments are very different in size, quality, shape, etc., the requirements for sorting methods, speeds and the number of sorting outlets are also different, so the types of sorters are also very complicated. Different sorters, different input devices and different sorting tanks can form a sorting system suitable for different needs.

3、 Sorting Chute

The sorting chute is arranged behind the sorting conveyor system. Usually there is a sorting chute at each exit of the sorter, and each sorting chute stores the goods of the same sorting destination. The more sorting chutes, the more destinations that can be sorted at the same time, and the larger scope of the sorting system serves. At present, smooth chutes made of steel plate or plastic are commonly used. In addition, some new material chutes with higher performance and higher cost performance are also used in the sorting system of some famous express companies.

4. Control Device and Computer Management

The main functions of the control device and computer management are as follows: one is to receive the information of the sorting object and to control the input device so that the sorting object can enter the sorter quickly and accurately according to the requirements of the sorter; the other is to continue the rolling sorting action and speed, enable sorting objects to be sorted quickly and accurately at the predetermined sorting chute, and various sorting can be completed at the same time. In the sorting system, signal detection, monitoring and safety protection, recording, monitoring and statistics of the operation data of each equipment are used for sorting operation management, comprehensive evaluation and analysis of sorting operation and equipment.