1.The brushless motorized roller does not have an electromagnet in the center which can solve the heating issue effectively.

2.This brushless DC drum motor is suitable for low-speed transmission.

3.The conveyor motorized roller adjust the motor voltage by constantly comparing the set speed of motor with the feedback signal so that it can adjust low speed back to set speed instantaneously even if the load weight changes.

4.The rotor of this type of DC powered roller is permanent magnet. The power consumption can be reduced more than 20% compared with variable frequency controlled three-phases induction motor. This motorized roller is more energy efficient.

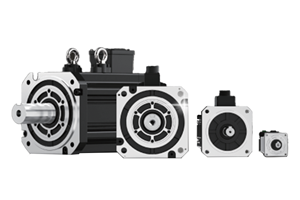

Servo motorized rollers are supplied for cross-belt trolleys. 67 mm outer diameter cylinders are processed by seamless steel tube. 1024-line high-precision encoders can achieve transient large torque and high-precision acceleration and deceleration control. Sorting weight range is 0 -50kg. It adopts permanent magnet servo motor design with CE certification.

1. Two working mode, single or double working direction.

2. The length and height of the telescopic conveyor can be adjusted randomly.

3. Reduce working time, decrease labor cost, avoid goods damages.

4. It is configured with innovative and high performance driving motor.

1.Great overload and stall capability for sorter servo motor.

2.Low inductance and zero mutual inductance.

3.Low speed torque, high balance accuracy, stable and high speed operation.

4.The sorter servo motor has large temperature gradient and excellent heat dissipation.