CAN-BUS Pick to Light System

Brand: BONRAY

Product origin: China

Delivery time: 30 days

Supply capacity: 1000 sets/day

1.Intelligent picking system, improved efficiency, less error rate for CAN-BUS pick to light system.

2.The CAN-BUS pick to light system has long distance for communication.

3.Convenient electronic label PTL system for setting up.

4.Longer life time and 7 color options for display of CAN-BUS light.

5.Low power consumption and adjustable data operation for CAN-BUS pick to light system.

-Introduction of CAN-BUS pick to light system:

For the operation of warehouse, the sorting procedure accounts for more than 40%. The speed and accuracy of picking directly determine the speed of delivery which is the most important part of improving customer service experience in logistics industry. However, the manual picking often has various of problems compared with digital picking system such as delivery failure always occurs during sales promotion. Therefore, the pick to light system has officially appeared and widely used nowadays. The digital picking system becomes an indispensable symbol of modern logistics industry informatizaiton.

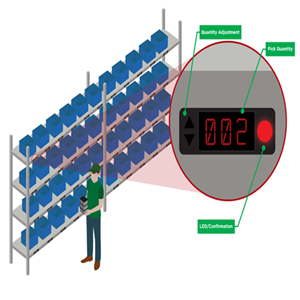

The PTL system stands for pick to light system. The basic concept of pick to light system is a visualized operation guidance and a instruction system. The digital picking system mainly controls a group of electronic devices installed on the shelf so that guide the pickers to perform the picking work through the light signals or displays correctly and quickly. The pick to light system is combined with electronic tags that are installed on the shelf to indicate the arriving and picking time or quantities of products. The reader of electronic label PTL system is hand-held or fixed reading. The antenna is used for passing the signal between the electronic tag and the reader. The electronic label PTL system uses the computer control system to transmit the information of orders to the electronic tags for guiding the pickers completing the work. The pickers press the confirm button on the controllers of pick to light system after the work done.

The working principle of pick to light system is not complex. The electronic tag receives the radio frequency signal from the reader after the tag enters the reader's magnetic field. The tag obtains stored information of product from the chip by induced current. The reader of digital picking system can read and decode the information. Then the information will be sent for relevant data processing.

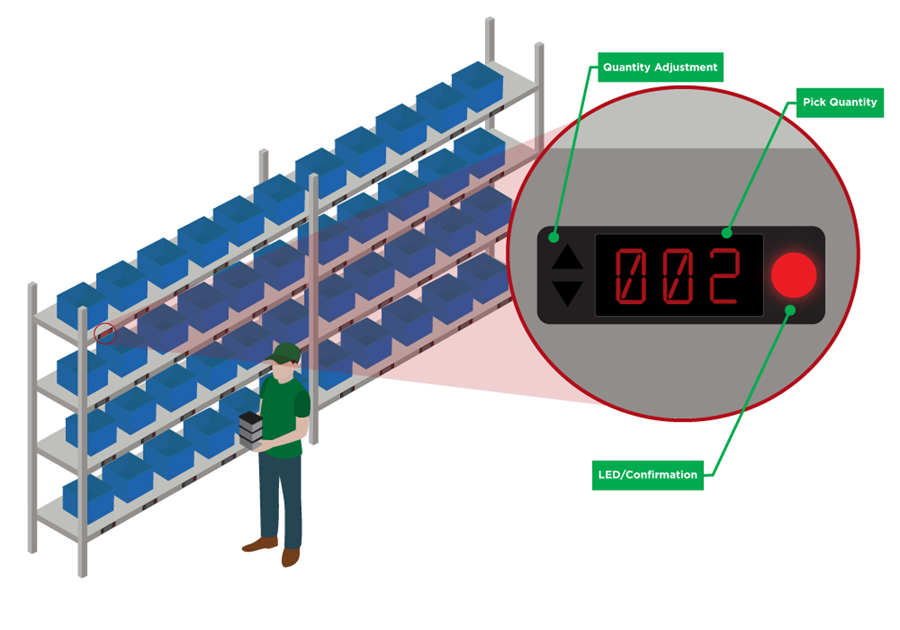

As this pick to light system, it adopts the Controller Area Network (CAN). The CAN-BUS provides an inexpensive, durable network that helps digital picking system's devices communicate with one another. An advantage to this is that electronic control units can have a single CAN-BUS interface rather than analog and digital inputs to every device in the system. Each of the device for pick to light system on the network has a CAN-BUS controller chip. All devices on the network see all transmitted messages. Every message has a priority, so if two nodes try to send messages simultaneously, the one with the higher priority gets transmitted and the one with the lower priority gets postponed. The CAN-BUS pick to light system is suitable for operating under -35℃ ~ 70℃. It also has multi-functional label design that one label is connected with scanner access, lighthouse control and area finisher.

-Advantages of CAN-BUS pick to light system:

1.The CAN-BUS pick to light system can realize the intelligent operation of picking, improve the efficiency of picking, reduce the labor intensity of the operators, the error rate and the number of employees.

2.The CAN-BUS digital picking system has long distance communication within 200 meters.

3.Fast set up programme for CAN-BUS electronic label PTL system that the picking label addresses can be quickly set up and viewed.

4.The CAN-BUS pick to light system has reliable design that all components are imported and it's electronic tag has 7 color programmable LED luminescent display options with more than 100,000 hours long life time.

5.The CAN-BUS digital picking system has low power consumption with the imported DC-DC power management chip for 9-14 wide voltage.

6.Adjustable data operation for electronic label of pick to light system under insufficient products' situations.

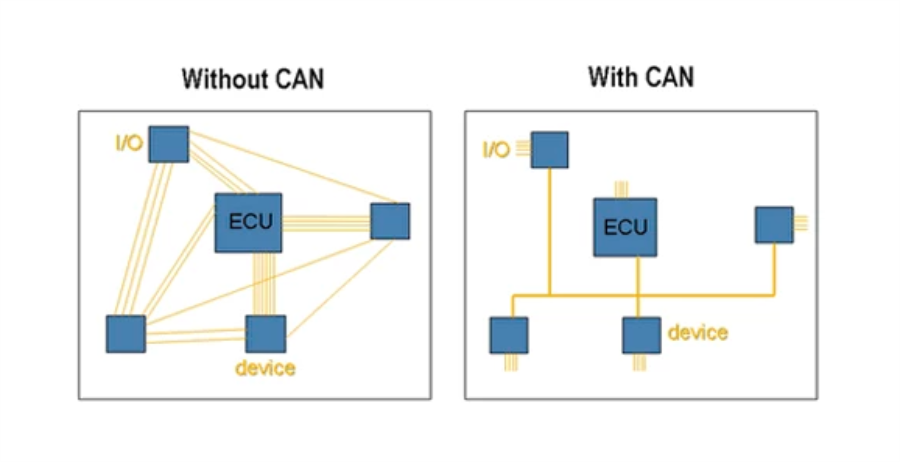

-The system architecture of CAN-BUS pick to light system:

1.Data Source: The data sources of CAN-BUS digital picking system are from the WMS, ERP and MES etc. The information also can be manually typed in.

2.Control PC: The pick to light system's control PC is used to download Ex-warehouse orders from WMS and sent the information to the CAN-BUS module through the network switch.

3.Network Switch: The network switch of electronic label PTL system can expand from 1 interface into multiple interfaces, it also knowns as bridges.

4.CAN-BUS Module: The CAN-BUS module of pick to light system controls the signal light and subtitle machine electronic label, and sends information back to the PC which achieves two-way communication.

5.Alarm Light: The pick to light system's alarm light is used in the operating area for promoting operational task.

6.Multi-functional Label: The multi-functional label of digital picking system is connected to the alarm light and code gun.

7.Electronic Labels: It is used to show the location, the number of ex-warehouse and issue instructions.

8.Code Scanner: The electronic label PTL system's code scanner can scan batch bar code to determine the distribution batch information or scan the product bar code to determine the distribution of commodity information.

-The scanner of CAN-BUS pick to light system:

The scanner of pick to light system is used for scanning the barcodes to determine the information. The operation time after charging is up to 3-4 days. Multiple code sweeping function is applied for this scanner.

Scanning distance | ≤100m |

Charging power | 5v-400mA |

Error rate | 1/20 million

|

Reading accuracy | 3.3mil

|

Working time | 3 to 10 days

|

Decoding rate | 2,00 times/s

|

Key life | 50 million times |

Laser operating life | 10,000 hours

|

Interface | USB, USB-COM

|

Trigger mode | Keystrokes/continuous/automatic induction

|

Anti-interference | No effect in bright light and sunlight |

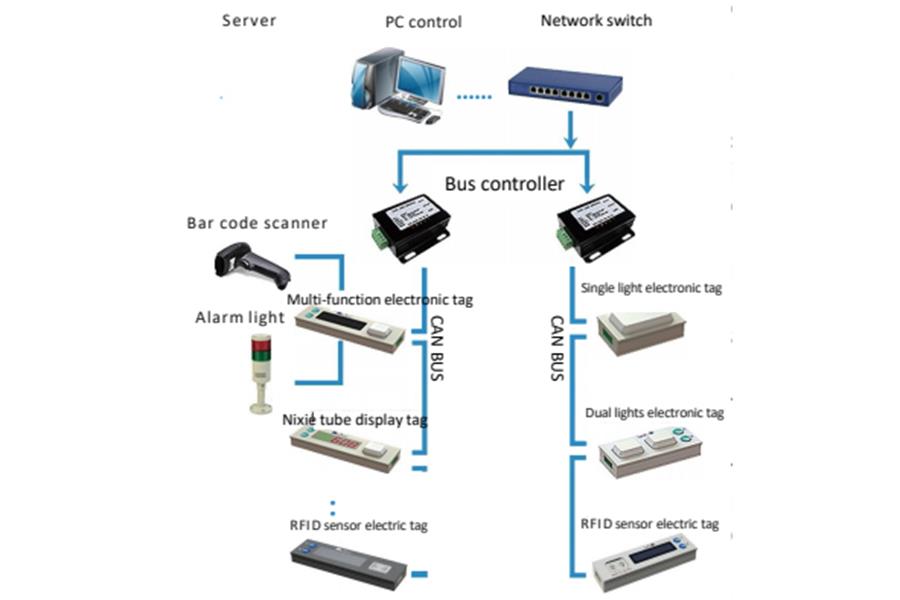

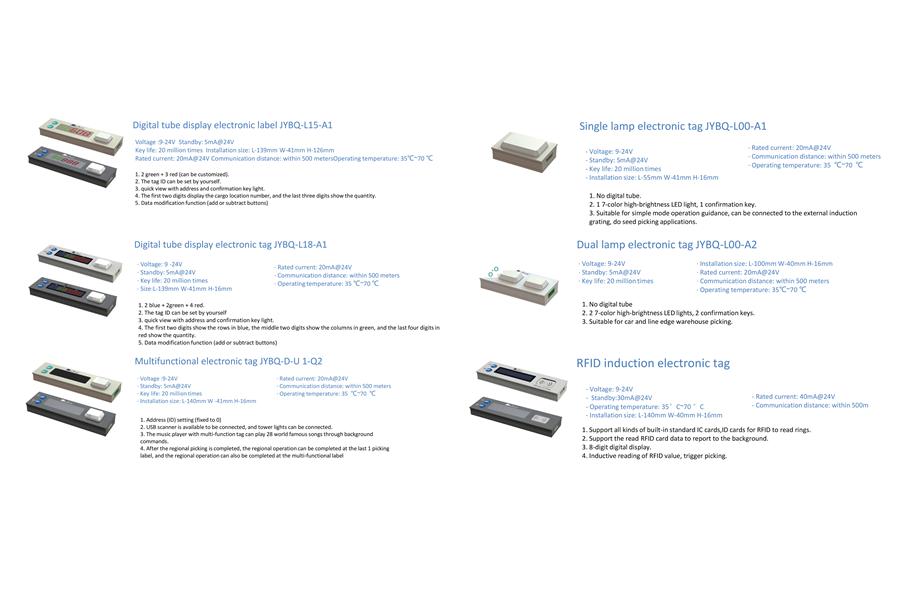

-Applicable electronic tags for CAN-BUS pick to light system:

-Use of CAN-BUS pick to light system:

The electronic label PTL system is widely used In the sorting and distribution of scattered goods in the industries of commercial chain, drug circulation, household appliances, electronic assembly, food and beverage, auto parts or other logistic industries.