Brand: BONRAY

Product origin: China

Delivery time: 30 days after receiving advance payment

Supply capacity: 3000 trolleys / day

1.This parcel sorter has wide application range that is suitable for items including plastic totes, cardboard carton, trays, stuffed envelopes and poly bags. The weight of items can be from 20 grams to 75 kilograms with dimensions from 50 x 50 x 1 millimeters to 1500 x 800 x 800 millimeters or customized.

2.This e-commerce sorter has high rate of sortation. single, twin, double-deck, and quad cell options as well as patented technologies like pre-sequencing allow the sorter to deliver orders out faster with production as high as 80,000 items per hour.

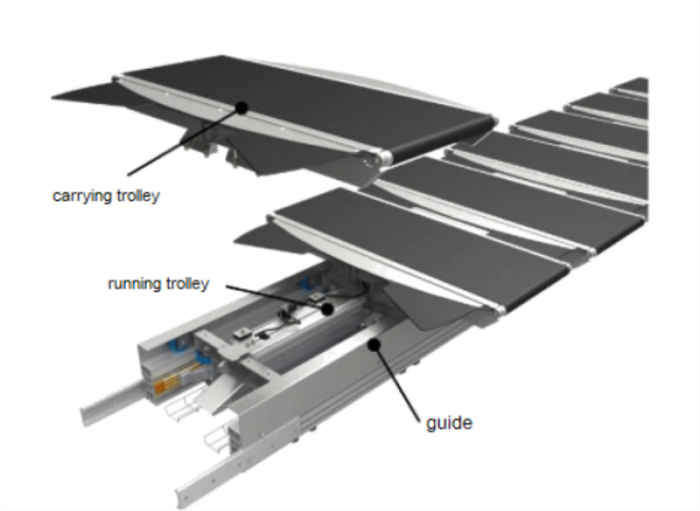

3.The body of the running trolley for cross belt sorter runs on the track with 2 wheels. Each wheel is equipped with a bearing. Even one person can push the 100-meter-long sorter by hand because of the low friction of each wheel.

4.A single sorting line of mail sorter can be increased up to 90 outputs. The output number can also be customized according to requirements.

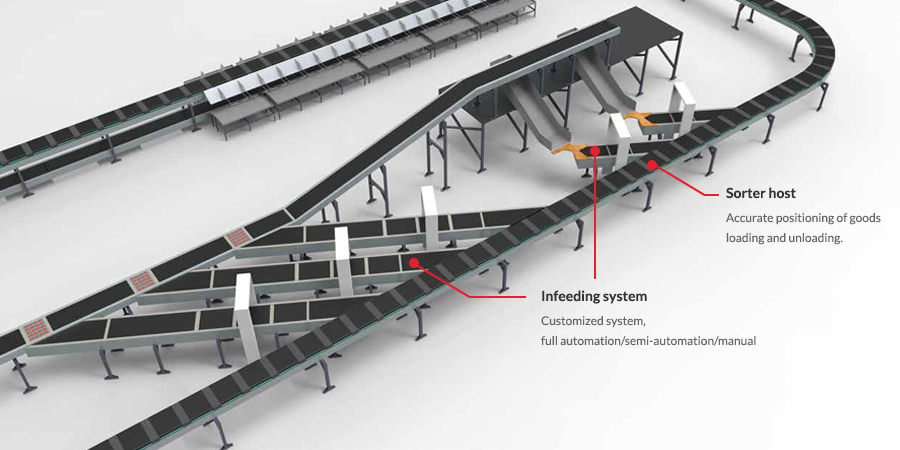

The cross belt sorter is a kind of automatic sorting system with strong design flexibility, stable performance and high reliability. The cross belt sorter system is mainly composed of a scattering belt conveyor, a separation belt conveyor and a visual recognition system. This parcel sorter is suitable for flexible sorting schemes of small and large sizes of goods transmission. It can greatly handle the conveying and sorting of large quantities packages for long time. The package sorter is commonly used in e-commerce, express delivery, clothing industry or books industry.

The cross belt sorter is composed of a group of trolleys which is generally form as a ring shape, even if a single trolley fails, it will not affect the use of other trolleys. Each of the trolley is the single sorting unit when the cross belt sorter processes large items. The belt on the trolley moves independently during the sorting action and can automatically adjust the unpacking angle of the items according to the direction of the grid so that to minimize the grid pitch. All items are transported in the transverse direction on the parcel sorter trolley which can maximize the transport efficiency. The signal communication of the running trolley adopts the design principle of plug and play. The trolleys of parcel sorter move along the track, the surface belt can rotate in a direction perpendicular to the movement of the trolley. The scattering belt of package sorter disperses the packages from the upstream to both sides and slightly draws the distance, then the separation belt draws and queues the packages. After scanning the barcode which is posted on the package, the package sorter can unload the packages to different slots according to their destinations. Comparing it with traditional logistics manual sorting operations, the cross belt sorter can achieve the purpose of classifying packages automatically, the mail sorter can greatly reduce manpower input and improve parcel processing efficiency.

The sorting action of the cross belt sorter will be adjusted differently according to the size, position and weight of different goods on the carrying trolley. For example, when lighter packages are being sorted, the starting acceleration of the belt of the trolley will be reduced to avoid slippage. On the other hand, if the item is small or in the middle of the loading trolley, the belt of parcel sorter will be activated in advance during sorting action to ensure the item can accurately fall into the corresponding grid.

This parcel sorter has an outstanding compact design with precision features such as double-cell oriented offloading. The package sorter we produce has the narrowest chute in close intervals which can save valuable floor space. Our cross belt sorter has short implementation cycle that can be quickly installed on site after commissioning. It has pretty low operating noise that the average noise of the whole machine is less than 70 decibels. The simplification of this cross belt sorter's structure also greatly reduces the difficulty and cost of maintenance.

-Applicable Parameters of Cross Belt Sorter:

Ambient Temperature | -5 ℃ - + 40 ℃ |

Applicable Humidity | 35% ~ 95% |

Rated Voltage | Three-Phase AC380V (1 ±10%) Unidirectional AC220V(1 ± 10%) |

Frequency | 50 (1 ± 2%) Hz |

Sorting Weight | 20 Grams to 75 Kilograms |

Carrier Size | 50mm x 50mm x 1mm to 1500mm x 800mm x 800mm or Customized |

Maximum Linear Speed of Sorter | 2.5 m / s |

Processing Capacity | 15000-21000 Pieces/ Hour/ Layer |

-Use of cross belt sorter conveyor:

The cross belt sorter is commonly used in e-commerce, warehouse and distribution industry. One of the highlights is that the mail sorter can greatly reduce energy consumption by mechanical transmission, the linear synchronous motors, automatic standby mode for induction conveyor, automatic variable offloading speed, low-friction plate under load transfer belts and patented permanent magnet linear motor technology